Migrate to the next level in your trailer’s automation

Extending the season or performing tasks in conditions that would normally halt work. The growing popularity of hydraulic wheel motors on trailers, slurry tankers, balers and many other kinds of implements working in forestry, agricultural and earthmoving conditions comes as no surprise.

And there’s no question about the advantages of trailers with driven wheels for tractor operators. They offer improved steering ability and prevent trailers from sinking into wet fields or forests, avoiding damage to arable land or tree roots. This saves time and money. Trailers with driven wheels even save fuel, because there’s no hauling of dead weight and heavy loads can be pulled with a smaller tractor. And the way to secure the biggest benefits is via Black Bruin’s On-Demand Drive System with multiple options, extending and upgrading it as you need.

That feeling of control

Tractor-trailer combinations are used in many different ways depending whether you work in the forest, on the field or on a construction site. At Black Bruin, we listen to customers’ needs attentively and develop our systems for an optimal response to all feedback. And there is a very clear customer demand for higher-level automation in the control systems. And there is a very clear customer demand for higher-level automation in the control systems. “Both end users and trailer OEMs want to know about options to make our system even smarter and more intuitive,” explains Black Bruin’s Product Support Manager Tero Pelkonen and continues: “But in some cases a simpler, not yet fully automatic system may be the right choice for some customers. We are able to make that decision completely individually and offer a different and personalized solution for each customer due to the modular structure of our system. The trailer and axle manufacturers also benefit from that possibility as it’s way easier to design all kinds of driven axles and integrate them on trailers when the manufacturer of the drive systems offers all kinds of versions.”

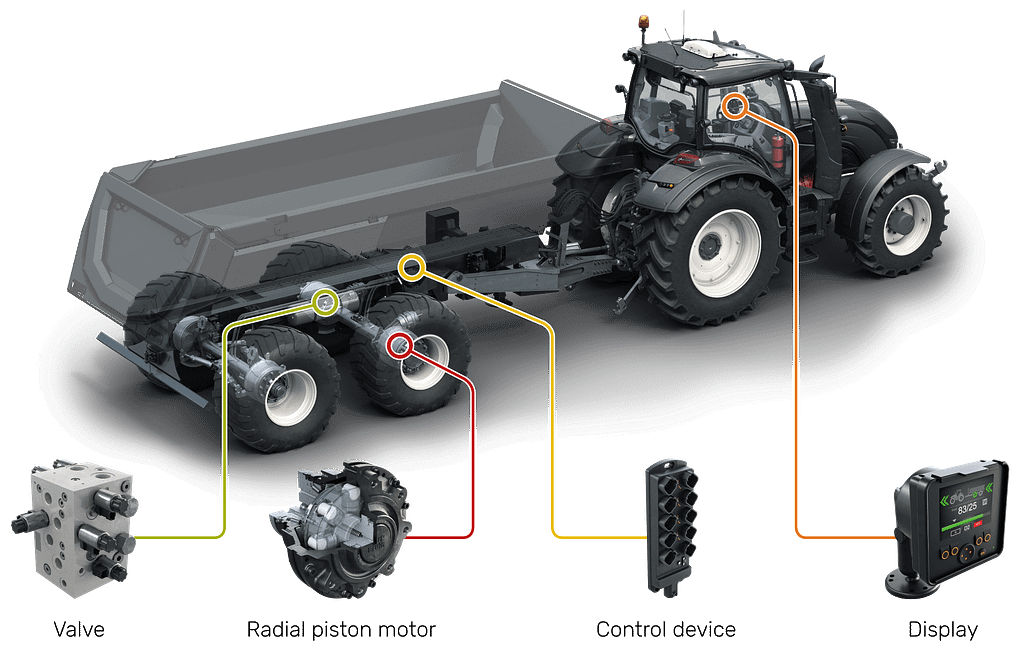

Black Bruin offers a complete On-Demand Drive System, covering hydraulic motors, valves and a control system – CTR201 for tractors and implements with ISOBUS and CTR101 for tractors without it. And our offering is expanding now with Hill Descent Control (HDC) for both systems, making several combinations possible.

Of the two alternative control systems, CTR201 is the more advanced option, coupled to the tractor’s ISOBUS, which provides the system with all the data needed to control the trailer’s wheel motors, including the tractor’s direction and speed. The display unit makes it easy to select the desired drive power, then the trailer automatically pulls in the same direction and at the same speed as the tractor. If required, the operator can also disengage the automatic system and control the trailer’s drive manually. When accelerating up to on-road speeds, the operator does not need to disengage drive – the system does that automatically at high speeds. CTR201 simplifies the operator’s work significantly and offers practicality that’s hard to beat.

CTR101 is a more manual system, in which engaging the drive and shifting between speed ranges are taken care of by the driver. The display unit of the CTR101 control system has the same updated and user-friendly interface as on the CTR201.

HDC feature now available for both systems

The HDC function helps control the vehicle combination and improves safety going down steep slopes. When the system is engaged, the wheel motors function as hydrostatic brakes. Using hydrostatic braking lightens the load on the actual operating brakes and prolongs their maintenance interval. The HDC function helps on steep slopes – in both forward and reverse gear.

When the HDC function is active, the wheel motors resist the wheel movement in the driving direction. You can adjust the HDC power level as you go.

Typical situations for HDC use are driving down and moving rearward on steep slopes:

In both situations, when activated, the HDC helps the vehicle maintain speed. It also prevents trailers from sliding off the path and causing damage to the environment.

See also

Development Engineer, ICT

We are looking for a specialist in testing and automation technology for testing and laboratory operations, combining hardware and code. The tasks involve diverse expert and development roles in testing and automation systems, logic, data, and ICT infrastructure.

Sustainable development draws power from respect

Most of us agree that technology is here to stay, no going back to the time without it. To save and restore the environment, more efficient and reliable technology is essential. As a 60-year-old innovation, Black Bruin hydraulic motors have indeed endured and are proud to be sustainable in the truest sense of the word.

John Henry Foster Co. of St. Louis complements Black Bruin’s network in the U.S. Midwest

We are pleased to share that, as of March 1st, John Henry Foster (JHF) has joined Black Bruin’s partner network as a system integrator. The partnership covers the states of Missouri, Kansas, Illinois, Iowa, and Kentucky. With this cooperation, we aim to support our growing customer base – particularly in new industrial applications.