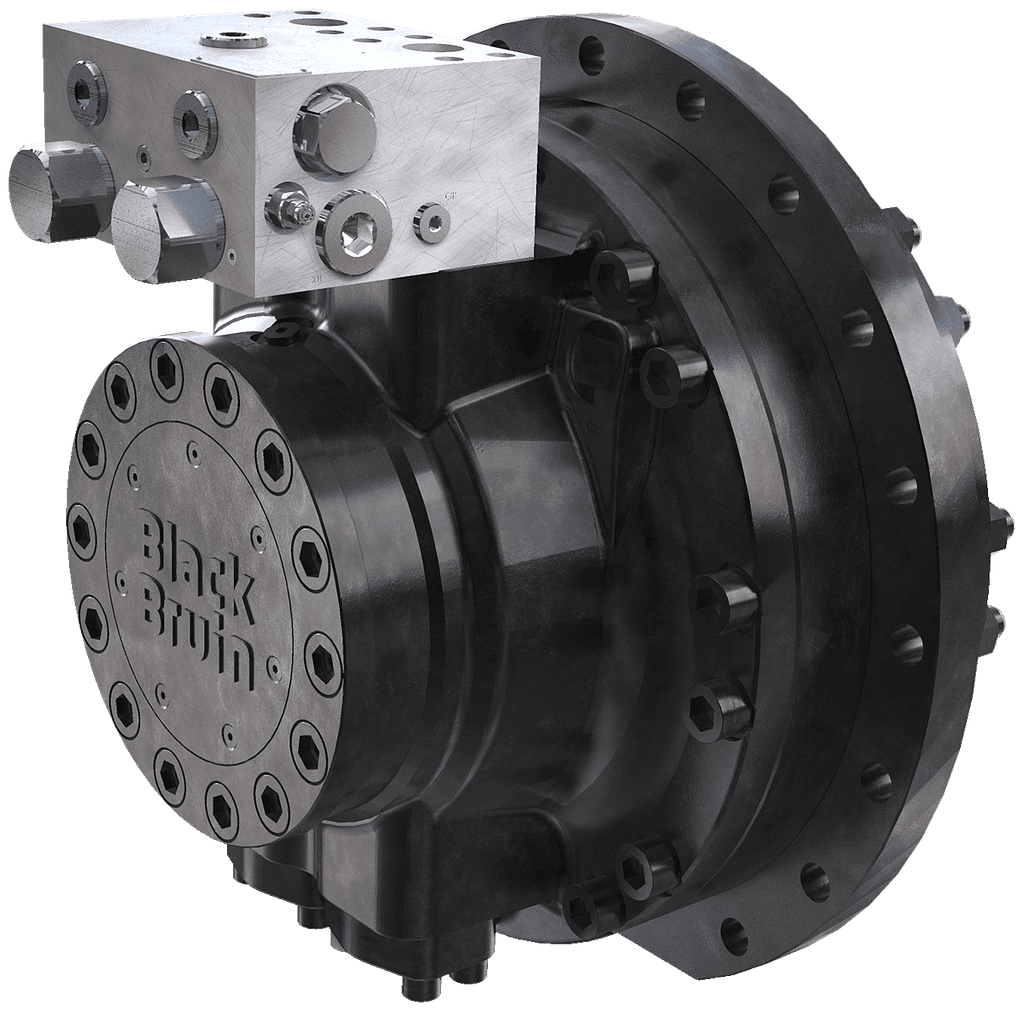

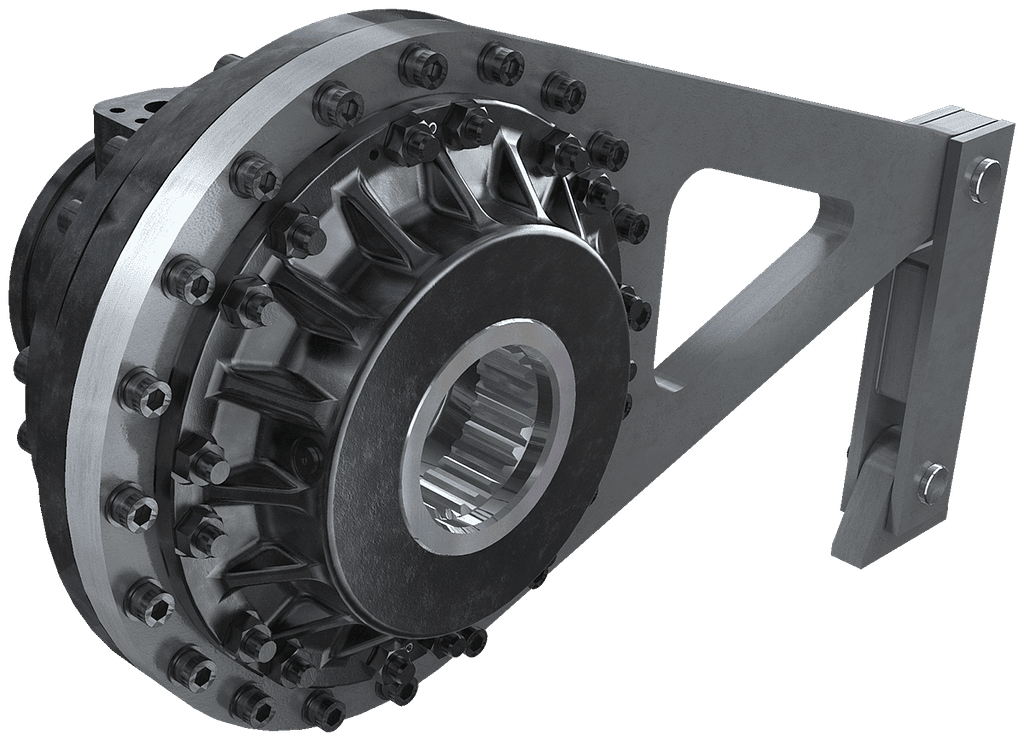

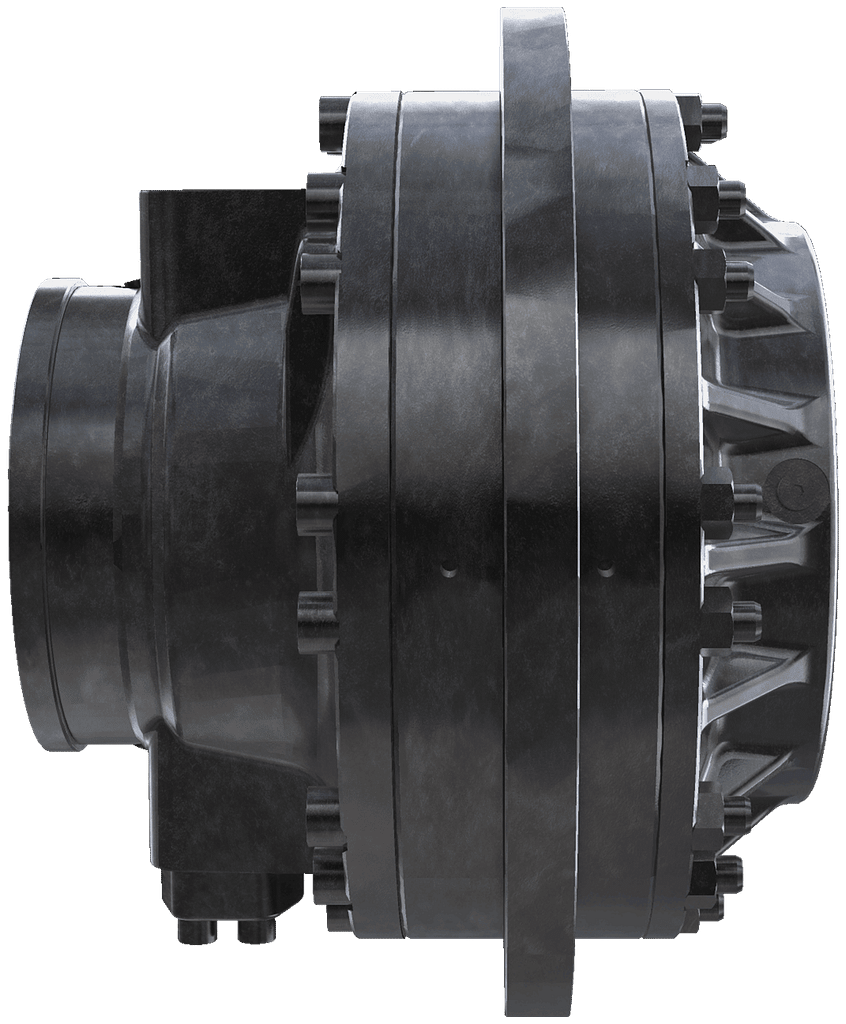

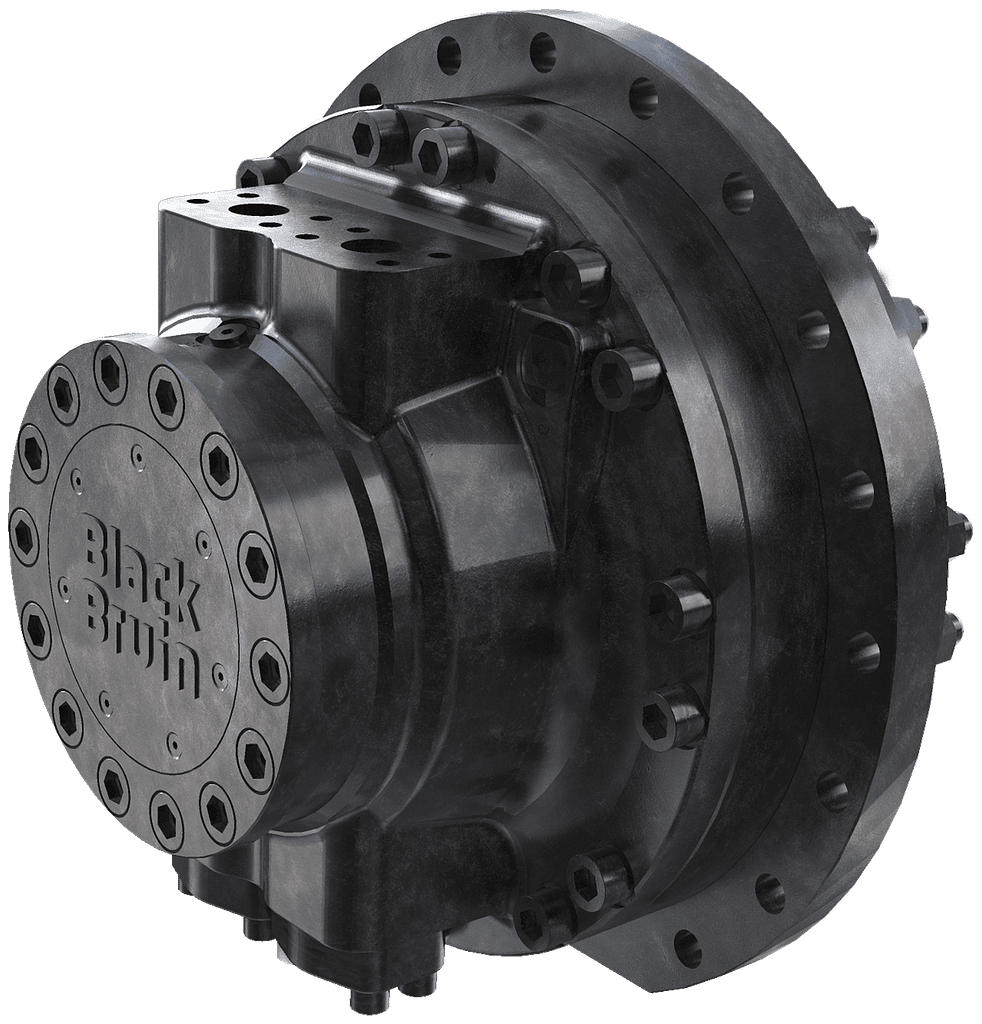

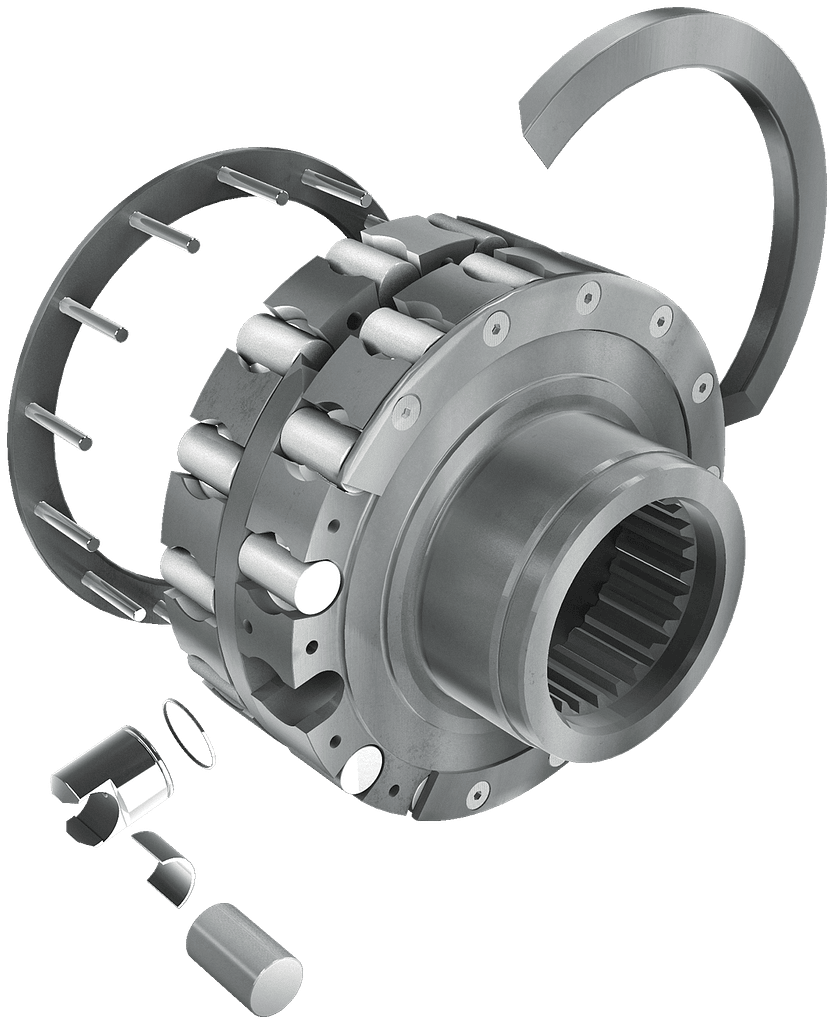

X-series hydraulic motors

Are you in search of a reliable, high-performance hydraulic direct drive motor that seamlessly integrates into industrial setups where compactness is a crucial factor, requiring few or no modifications or conversion costs? The new X-series is matching market demand in various recycling, marine and offshore, construction, mining, material handling, and pulp and paper applications.