Construction

If your motor can make it here, it can make it anywhere

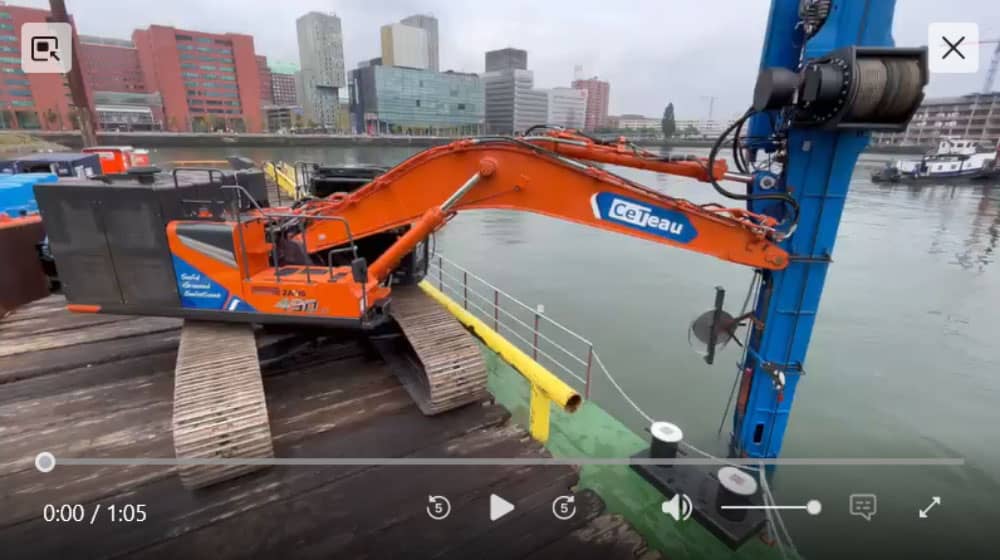

A contractor and a machine builder, the Dutch company CeTeau is on a mission to give people and businesses a good solid place and safe space to live and operate in, reclaiming land from the sea all over the globe. With their core business of manufacturing and installing prefabricated vertical wick drains, PVDs, CeTeau is enabling faster, safer and more economical ground improvement and land reclamation solutions for soft soils with a high clay/silt content. “It is very similar to the perhaps better known pile driving machines,” says CeTeau’s Managing Director Tijl Pieter de Zwart and continues: “But instead of hammering, our machines do ‘stitching’, pulling the PVDs down with a powerful winch, which needs to change direction really fast. And that’s where we need the most reliable power source.”

It’s all in the winch – and the motor

Roads, railways, dikes and airports. Harbor construction. Urban and industrial sites: There are numerous applications where the installation of CeTeau’s PVDs helps drain off water fast to reduce settlements and also reduces pore pressure to prevent liquefaction and make the soil safe, solid and secure for construction work. The PVDs are installed vertically into the soft soil creating drainage paths in the highly permeable soil. Working to depths of up to 50 metres, the winch is the most essential component in CeTeau’s solutions and their customers’ operations. “It’s continuously making short cycles, changing direction almost every minute, which is hard on the motor, and is just too much for most models,” Tijl declares and continues: “We like to say to the machine operators we are training that they must not come home unless they’ve made at least 1 000 points in one shift.”

That pretty much describes the role of the winch in ground improvement operations compared to its role, for example, on board ships, where its force is deployed in a totally different direction and its duties are less 24/7 – but obviously equally important. Against this background it is also easy to understand the importance of the power source, the hydraulic motor that makes it all possible for the winch. It must be robust and powerful… and never stop working.

Developing solutions together with Black Bruin

The cooperation of CeTeau and Black Bruin goes back some 20 years. Tijl describes why he especially appreciates the cooperation between the two companies: “There’s always been and continues to be a strong customer focus. We develop things together, and Black Bruin have an excellent capability in customizing their products, – for us it’s the hydraulic motors – which means that we can offer our customers truly custom-made solutions. The dialogue is smooth and easy, too, since it’s with the same Black Bruin people that I’ve been communicating with for the last 20 years.”

BB – S – X – tandem

Throughout the years, CeTeau have been using Black Bruin’s BB7 motors, the S-series motors and the very recently launched X-series. A special ‘tandem’ solution has also been put together where the S-series and X-series motor work together in CeTeau’s applications for maximum strength and availability. According to Tijl, this special construction offers some unprecedented advantages. “Our customers’ operations are characterized by the need for very high and variable power, which is demanding a lot from the motors. With the tandem motor solution, we can freewheel one motor and let the other one do the work when the need for power is not at its peak. And when more power is needed, the pushing down phase, we put both motors on the job. For example, in many parts of Portugal and Spain, there is often first a dense layer of earth and then a softer layer. These require different boring speeds. In the dense layer the motor needs to be powerful, whereas in the soft layer we do not need power – we need speed. That’s what makes such a tandem solution just about perfect for us. And the motor is the main part of our equipment.”

According to Black Bruin’s Sales Manager Kari Laitinen, the tandem construction may consist of various combinations of two Black Bruin motors working together in tandem: “In some cases it could even be two BB7 motors mounted on opposite sides of the terminal device. We like to listen very carefully to the feedback on the applications and be open minded.”

Geographical expansion

Named after the ancient sea goddess in Greek mythology, and also having the word eau in the name, for CeTeau it is all about water. The area to be improved may not be next to the ocean, but the problem that CeTeau´s solutions are solving is always about improving the quality of soil containing just too much water. Currently the main focus of CeTeau is on the “exponentially developing Asia with all those river deltas,” as Tijl describes it. “Volume-wise it’s by far the biggest geographical area in our current business. There are huge sites there with 10-20 of our machines operating non-stop.” Of course, CeTeau are active elsewhere in the world, too, for example in Europe, notably in their home country Holland. “They tend to be smaller jobs but at the same time very important and interesting offshore projects, including the improvement of ground underwater – preparing poor quality soil for construction, houses for people to live in and infrastructure to give them a better life.”

Another example Tijl gives of the importance of meticulous, high-quality ground improvement is in Norway, where houses suddenly disappeared due to the lack of it. “Safety is essential in our work, too, like in almost all businesses,” Tijl declares.

This year CeTeau are expanding to North America. Tijl is happy that Black Bruin are already well established there. “I know they have been serving North American customers for decades, meaning that they also have a well-functioning service operation there. That will surely help us gain ground in that vast market, too.”

See also

The Art(o) of knowing it inside out: HydroSystem is Black Bruin’s long-trusted partner in Finland

In gratitude for your hard work and commitment from 2000 to 2021. HydroSystem’s Arto Haataja deservedly receives Black Bruin’s Golden Distributor Award.

Fish biting and bear motors selling well in Norway

The distributor for Black Bruin in Norway, Hydraulikkteknikk was founded in 2003, nowadays employs 18 people and has its business premises near Oslo. The company has been distributing Black Bruin motors since the start of 2003, when part owner Morten introduced the motors to the company, he himself having worked with Black Bruin motors since 1993 with his previous employer.

SID chooses the Black Bruin S-series: powerful and reliable direct drives for shredding applications

Black Bruin helped SID to simplify the machine design by replacing a small motor and a planetary drive. The motor chosen was customized in order to meet SID technical standards and special requirements.